Threaded spindles for levelling feet

Precise height adjustment - Threaded spindles from norelem for millimetre-precise adjustments

High load capacity and durability - Qualities that count

Advantages of threaded spindles

Efficient and cost-effective solutions with threaded spindles from norelem

Precise height adjustment - Threaded spindles from norelem for millimetre-precise adjustments

A threaded spindle is a component used in machine and plant construction. They work by converting rotary motion into linear motion. A threaded spindle is a threaded rod that is screwed into a suitable counterpart. When the spindle is rotated, this counterpart moves up or down along the thread.

This creates an upward or downward movement. This movement enables precise height adjustment and can be used to lift or lower heavy loads. It is therefore no wonder that the threaded spindle is frequently used for levelling and for linear adjustment mechanisms. Be it in mechanical engineering, furniture manufacturing or other industries.

High load capacity and durability - Qualities that count

Threaded spindles are made from robust materials such as steel or stainless steel. This ensures corrosion resistance and mechanical stability. Stainless steel is particularly suitable for environments where moisture or aggressive substances are present.

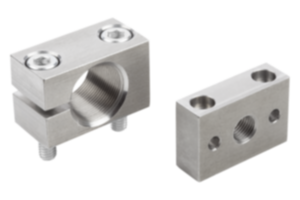

A threaded spindle may be composed of several components. Each one of these components ensure the functionality and efficiency of the spindle.

Spindle rod: The spindle rod is the main element of a threaded spindle. It is usually cylindrical and has a thread running along the entire length. This thread enables the linear movement when the spindle rotates and is available in different thread sizes (e.g. M6 to M24).

Thread profile: The thread itself can have a variety of profiles. For example, trapezoidal threads are suitable for high loads, while metric standard threads can be used for universal applications. The profile determines the type of movement, load capacity and power transmission efficiency.

Ball joint: Some threaded spindles have a ball end or joint at one end, giving the spindle more flexibility. When combined with a plate, a spindle with ball joint can compensate for uneven surfaces. This is particularly useful for irregular floors or machine feet.

The norelem range includes threaded spindles for levelling feet or swivel feet. These differ mainly in their flexibility.

Swivel feet are flexible and can adapt to uneven surfaces. The ball joint can rotate and compensate for slopes. These items are ideal for any equipment or machines that need to be levelled on uneven ground.

Levelling feet, on the other hand, provide height adjustment. They are better suited for flat surfaces where the main requirement is rigid positioning.

Threaded spindles for swivel feet are made from steel or stainless steel

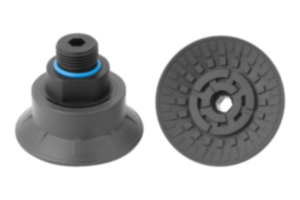

Swivel pads consist of a threaded spindle and a plate. The steel or stainless steel threaded spindles for swivel feet are highly suitable here.

The stainless steel spindles are made of 1.4350 stainless steel and are untreated (bright). The steel versions are blue passivated.

To calculate the actual height of the entire swivel foot, the following formula must be applied:

Total height of swivel foot = L + L1 + 22.5 mm

L stands for the length of the threaded spindle and L1 for the height of the hex collar.

These threaded spindles can be combined with the following plates:

- Antistatic plates for swivel feet

- Stainless steel plates for swivel feet

- Swivel feet plates with vibration absorption

- Extended die-cast zinc plates for swivel feet

- Die-cast zinc or stainless steel plates for swivel feet

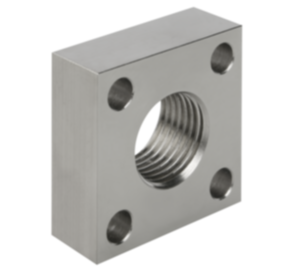

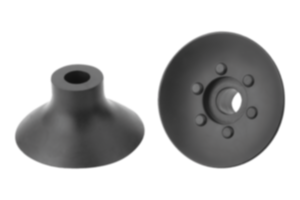

Threaded spindles for levelling feet

norelem offers two different variants of threaded spindles for levelling feet. Both are available in steel or 1.4305 stainless steel. The steel spindle is blue passivated and the stainless steel spindle is bright.

The standard threaded spindle for levelling feet can be combined with every plate. The height of the entire levelling foot is calculated as follows:

Total levelling foot height = L + 30 mm

L stands for the length of the threaded spindle.

The threaded spindles for the ECO levelling feet are suitable for a certain plate. The ECO levelling foot plate has a thermoplastic elastomer anti-slip pad. This absorbs vibrations and prevents the levelling foot from slipping.

Advantages of threaded spindles

Threaded spindles are a central element in the structure of levelling feet and offer a range of advantages. This makes them ideal for industrial applications. We have summarised the individual advantages for you here so that you can get a rough overview.

- Precise positioning and flexible height adjustment: Threaded spindles enable very precise positioning, as the motion is controlled by the thread. This is ideal for applications where precise manoeuvring is required, such as CNC machines or measuring instruments.

- High permissible load: Threaded spindles are able to bear high loads because the thread distributes the load over a wide contact area. This makes them ideal for applications that require a high load capacity, such as in the machine tool industry.

- Use of durable materials: Threaded spindles are often made from robust materials such as steel or stainless steel. Both materials ensure a long service life, even under demanding conditions. This makes the parts resistant to wear and external influences.

- Combination options of threaded spindles and plates: The design of the norelem spindles permits flexible combination with a variety of plates. Any threaded spindle can be used with any plate. This offers flexible solutions for a wide range of applications!

- Wide range of products: norelem offers spindles in different types for swivel feet and levelling feet. They are available with various thread sizes (M6, M8, M10, M12, M14, M16, M20, M24). They are also provided with the following lengths: 15, 25, 30, 40, 45, 50, 66, 70, 80, 85, 90, 100, 120, 125, 150, 200 mm.

This diversity enables precise tailoring to the specific requirements of your application.

Efficient and cost-effective solutions with threaded spindles from norelem

norelem offers high-quality spindles for levelling feet that enable more than just precise height adjustments. Our components for machine and plant construction also impress with efficiency and durability.

With a wide range of sizes and materials such as steel and stainless steel, we cover a diverse range of applications.

Buying threaded spindles from norelem has clear advantages!

In addition to high quality, you benefit from an excellent price-performance ratio, fast delivery and expert advice.

We ensure that every threaded spindle meets high standards. This makes them the ideal solution for anyone looking for efficiency and cost-effectiveness.