Electric positioning stages

Electric positioning stages are versatile linear systems that are ideal for use as traversing and positioning modules. The positioning stages and rotary stages ensure that components, limit switches, sensors, grippers and stops can be positioned with an accuracy to within a hundredth of a millimetre. Electric positioning stages from norelem enable the user to create a huge variety of construction solutions to tackle guiding and positioning tasks. Areas of application include machining centres within handling systems, in machine tools or in measuring equipment.

Electric positioning stages are low-noise and low-maintenance despite the motor and are a popular alternative to the manual versions, which norelem also has in its product range. The modules for motorised adjustment and positioning tasks are suitable for traversing speeds of up to 1.2 m/min. and objects weighing up to 10 kg. A radial play of less than 0.02 mm and a backlash of less than 0.04 mm are proof that the electric positioning stages work and function very precisely in practice.

The short version is available in size 8 and the long version in size 12. The electric positioning stage can be ordered with a stepper motor and as a variant with a stepper motor and positioning control. The variant with a stepper motor and positioning control includes user-friendly programming software, which can be downloaded free of charge.

Note: Positioning rotary stages are only available in size 12 with a coaxial drive.

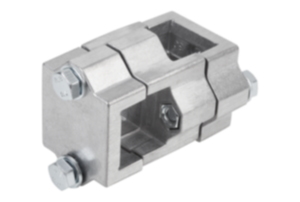

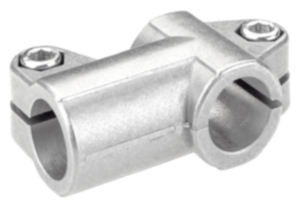

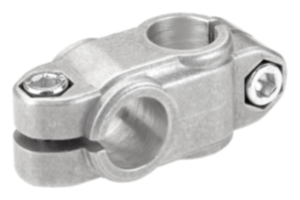

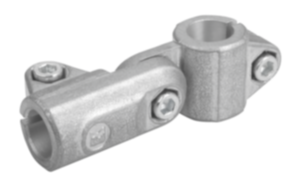

In general, all drive modules are made from high-quality materials and components. The plain bearing bushes and spindle nuts are made of high-performance plastics. This makes the positioning stages extremely robust and durable for the application. This ensures problem-free permanent operation of the units in practice, even with a duty cycle of 100%. The drive elements such as spindles or shafts are all made of stainless steel and the body is made of anodised aluminium.

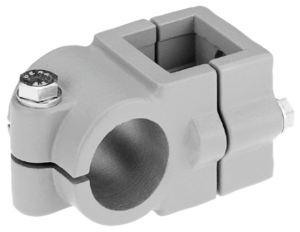

To make work easier for the designer and developer, the motorised positioning stages are compatible with all other components of the same size (typical norelem modular system). This enables a high degree of flexibility in order to ultimately realise customised solutions. Multiple systems, including the attachment of end position sensors, are achieved in a simple manner. A wide range of accessories such as proximity switches and the corresponding sensor holders round off the product line.