Push-pull toggle clamps, manual clamps

Push-pull toggle clamps and manual clamps - versatile tools for industrial machining

Robust solutions for demanding applications - the push-pull toggle clamps from norelem

Push-pull toggle clamp components

How a push-pull toggle clamp works

The manual clamp, a flexible tool for precise clamping and mobility

Productivity and safety in the workplace

Find the perfect clamp at norelem and increase your productivity!

Push-pull toggle clamps and manual clamps - versatile tools for industrial machining

Push-pull toggle clamp and manual clamps are clamping devices that are used in a variety of applications in a range of industries. The clamping devices are used to securely fixate and hold workpieces. Push-pull toggle clamps and manual clamps are crucial for machining, assembling and securing components. They can be found in fields such as metalworking, woodworking, machine construction and other industries.

Push-pull toggle clamps use a push rod with a threaded spindle that is moved by a toggle system to generate the clamping force. They are known for their robust construction and their ability to transmit high forces. Push-pull toggle clamps are often used in demanding applications where high strength and stability are required. They provide secure and reliable clamping of workpieces and are available in various sizes and styles to meet specific requirements.

Manual clamps on the other hand, are manually operated clamping devices that often use a push rod or lever mechanism to clamp the workpiece. Manual clamps are ideal for applications where rapid adjustment and precise setting of the clamping force is required.

The importance of push-pull toggle clamps and manual clamps extends across various industries. The clamping devices are indispensable tools for the secure clamping and machining of workpieces in a wide range of applications. Some industries in which the clamping fixtures are of great importance are:

- Metal processing and machine construction: Here, push-pull toggle clamp and manual clamps are used to hold workpieces in place during e.g. sawing, grinding, milling and welding. They enable precise machining of metal parts and help to increase efficiency and accuracy.

- Woodworking: In the woodworking industry, push-pull toggle clamps and manual clamps are used in the manufacture of furniture, cabinets, doors and other wooden products. They are used to hold wooden panels, boards and blocks securely during sawing, planing and gluing.

- Electronics industry: In the electronics industry, push-pull toggle clamps and manual clamps play a role in the manufacture of circuit boards, electronic components and equipment. They assist in the assembly and fastening of components and contribute to quality assurance in production.

Robust solutions for demanding applications - the push-pull toggle clamps from norelem

Push-pull toggle clamps are versatile clamping devices. They are used in various industries for the secure clamping of workpieces during machining or assembly. Their functionality enables secure clamping, which makes them indispensable tools in production.

Push-pull toggle clamp components

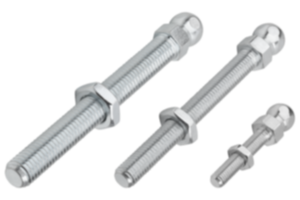

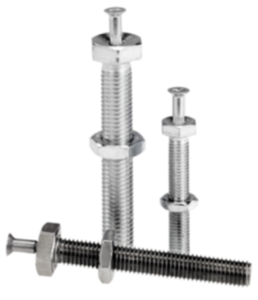

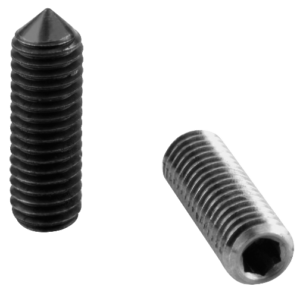

A typical push-pull toggle clamp consists of several components. The push rod is the central element of the clamp. It is usually a rigid rod with a threaded spindle that is moved by a toggle mechanism.

This push rod with threaded spindle is moved by a toggle mechanism that exerts the clamping force. The push rod is moved forwards or backwards as the mechanism is actuated. The workpiece is clamped or released depending on the position of the push rod. A grip or lever enables the user to manually actuate the clamp and generate the clamping force.

On the end of the push rod there is a threaded spindle with a thrust pad that clamps the workpiece. The thrust pads or threaded spindles are interchangeable and can have different forms to adapt to the geometry of the workpiece.

How a push-pull toggle clamp works

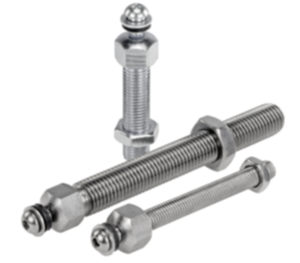

First, the push-pull toggle clamp is positioned so that the thrust pad nearly touches the workpiece being clamped.

The toggle mechanism is now actuated, moving the push rod forwards. The thrust pad is pressed against the workpiece which is now securely clamped. The clamping force can be regulated by screwing the threaded spindle in or out, the closer the thrust pad is to the workpiece before the toggle mechanism is actuated, the higher will be the clamping force.

The workpiece can now be machined or assembled while it is securely and rigidly fixated.

Once machining or assembly is complete, the push-pull toggle clamp is released by reversing the toggle mechanism to ease off the clamping force and so release the workpiece.

The norelem range includes nine different push-pull toggle clamps. You can use the filter function on the page to easily find the appropriate push-pull toggle clamp.

Included in these nine standard items are two types of mini push-pull toggle clamps, each with a clamping force (N) of 500 g. The mini push-pull toggle clamp have a very low overall height and lock in the closed and open handle position. They can therefore be used under compressive or tractive loads.

In direct contrast to the mini push-pull toggle clamps are the heavy-duty push-pull toggle clamps. This clamp is equipped with a stroke limiter for advancing and retracting and has a clamping force of up to 7 kN.

The following products in the norelem range may also be of interest to you:

- Push-pull toggle clamp without mounting bracket

- Horizontal toggle clamps with push rod

- Push-pull toggle clamps with mounting bracket

The manual clamp, a flexible tool for precise clamping and mobility

The norelem range includes two versions of these manual clamps.

- 05666 Vertical manual clamp with hole pattern on the front: This is made from steel and has a ball grip lever. The clamping torgue is 55 Nm and the retaining torque is 110 Nm.

- 05667 Vertical manual clamp with hole pattern on the front: This clamp is also made from steel, but has two ratchet stops. One ratchet stop for opening angles 45° to 65° and one for 90° to 120°. It also has an end stop for opening angles. The clamping torque for this manual clamp is 160 Nm, the retaining torque is 320 Nm.

Productivity and safety in the workplace

Push-pull toggle clamps offer a number of advantages that make them indispensable tools in various industries. Among them:

- High clamping force: These toggle clamps are capable of generating high clamping forces to hold even heavy or irregularly shaped workpieces securely. This enables secure fixation during machining or assembly processes.

- Robust design: Push-pull toggle clamps are robustly constructed and made from materials such as high-quality steel. The solid construction makes them durable and resistant to wear and stress.

- Versatile uses: These standard parts are used in a wide range of applications. Above all, the wide range of push-pull toggle clamps from norelem facilitates the different utilisation of these standard parts.

- Simple operation: Push-pull clamps are easy to operate and require no special training or knowledge. The simple thrust mechanism means they can be operated quickly and efficiently which streamlines and speeds up work processes.

- Safety in the workplace: By securely clamping workpieces in place, toggle clamps help to prevent accidents and injuries in the workplace. They provide stability and safety during the machining process and protect against potential hazards.

Manual clamps also offer a number of advantages that make them practical tools. The manual operation permits quick and easy adjustment of the clamping force as required and offers full control over the clamping process. This flexibility enables their use in a wide range of industries and applications. The compact design facilitates handling and storage of these standard parts.

Find the perfect clamp at norelem and increase your productivity!

Discover our wide range of clamping fixtures. Irrespective of whether you work in metalworking, woodworking or assembly, norelem offers you the perfect clamp for your requirements. You can increase your productivity and optimise your work processes with high-quality clamps from norelem.