{"product":{"productId":"agid.2692","price":264.83,"name":"Centring clamps with ball or hexagon segments"},"currency":"EUR"}

Material

Body 1.2842.

Ball and hex segments 1.4112.

Tension spring 1.4310.

Ball and hex segments 1.4112.

Tension spring 1.4310.

Version

Body hardened and black oxidised.

Ball and hex segments hardened and ground.

Ball and hex segments hardened and ground.

Show more

Show less

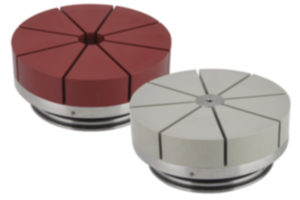

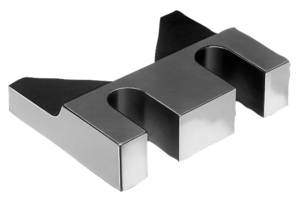

Centring clamp with ball segments, Form A

from

€264.83

plus sales tax

plus shipping costs

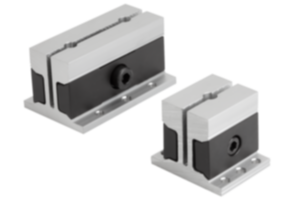

Centring clamp with hexagonal segments, Form B

from

€328.83

plus sales tax

plus shipping costs

Description

Material

Body 1.2842.

Ball and hex segments 1.4112.

Tension spring 1.4310.

Ball and hex segments 1.4112.

Tension spring 1.4310.

Version

Body hardened and black oxidised.

Ball and hex segments hardened and ground.

Ball and hex segments hardened and ground.

Technical Data

Repetitive accuracy ±0.025

Concentric accuracy ±0.05

Concentric accuracy ±0.05

Application

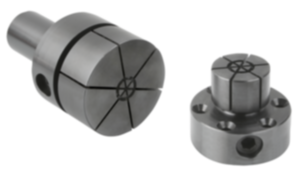

For centre positioning and clamping in blind holes. Operated from below, manual or automatic using pneumatics or hydraulics.

Advantages

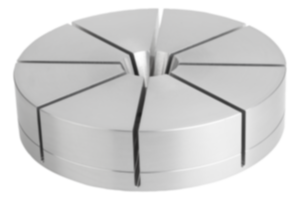

- Precise self-centring.

- Distortion free clamping.

- Large spread range.

- Low overall height.

- Positive down force.

- Distortion free clamping.

- Large spread range.

- Low overall height.

- Positive down force.

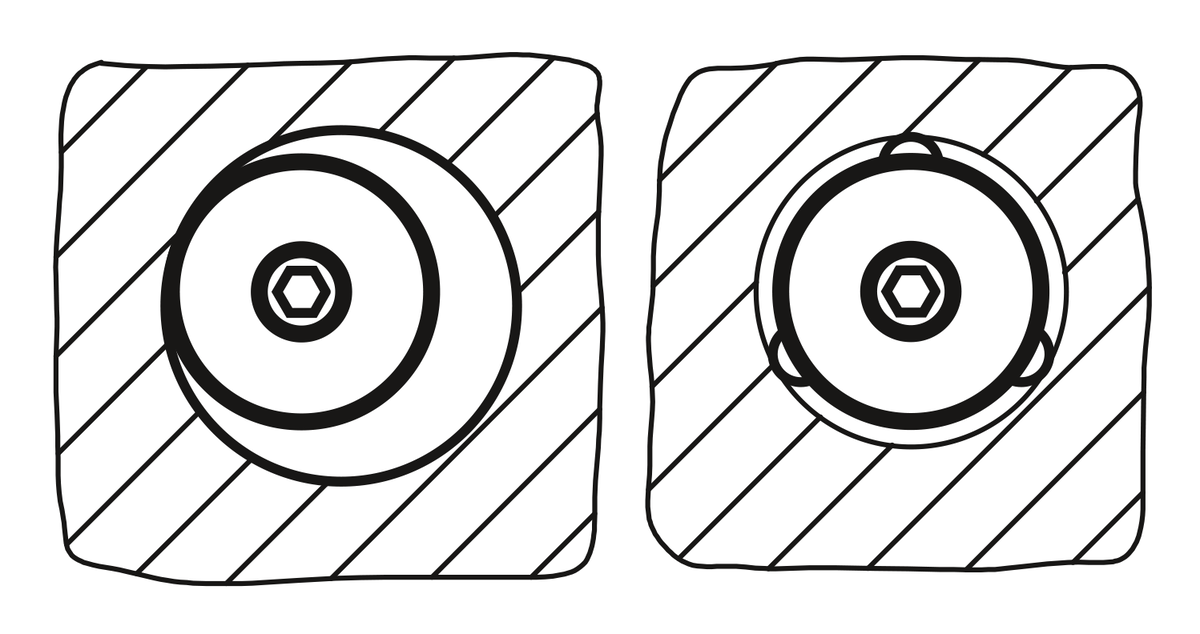

Drawing reference

Form A:

With balls for holes where light marking is acceptable.

Form B:

With hexagons for sensitive hole surfaces.

1) Mounting aid:

pin to accurately position the mandrel segments.

With balls for holes where light marking is acceptable.

Form B:

With hexagons for sensitive hole surfaces.

1) Mounting aid:

pin to accurately position the mandrel segments.