Cam action indexing plungers, barrel slide bolts

Cam-action indexing plungers, barrel slide bolts from norelem

What are cam-action indexing plungers?

What are barrel slide bolts?

The various standard parts in the cam-action indexing plungers, barrel slide bolts product family

norelem as your partner for cam-action indexing plungers and barrel slide bolts

Cam-action indexing plungers, barrel slide bolts from norelem

Cam-action indexing plungers and barrel slide bolts are standard parts that play a decisive role in the industry. The standard parts are used to safeguard systems and control access to various areas. Both standard parts serve to protect employees, systems and valuable resources. Cam-action indexing plungers and barrel slide bolts differ in terms of their functionality and areas of application.

Regardless of whether they are used in machine rooms, storage areas with hazardous substances or other critical zones – cam-action indexing plungers are designed to prevent unauthorised access. This ensures the safety of employees and the integrity of production processes. In contrast, barrel slide bolts focus specifically on securely closing and locking gates, doors or other openings within the industrial system.

One thing is certain, however. Both standard parts are considered key components in the industrial environment. The combined application of these standard parts enables a holistic approach to safeguarding industrial systems.

What are cam-action indexing plungers?

Cam-action indexing plungers are safety devices that are used to control access to specific areas within production systems or industrial facilities. They are widely used in various areas where the targeted control and safeguarding of access areas is of great importance. In industrial systems, they are used to restrict access to sensitive production areas in order to ensure the safety of employees and the protection of system resources.

In logistics and warehousing, cam-action indexing plungers are used to control access to storage areas or high-bay warehouses and prevent unauthorized access. In machine construction, they secure machines and systems against unauthorized access, while in public institutions such as schools, universities or authorities, they help to reserve certain areas for authorised personnel.

The versatility of the plungers makes them indispensable safety components in a wide variety of environments where the protection of people and machinery is paramount. The operating principle of cam-action indexing plungers is usually quite simple, but extremely effective.

The cam-action indexing plunger is placed in the desired position to block access to an area. Most cam-action indexing plungers use a bolt mechanism. This bolt is moved into the locking position manually or by another power source. In this position, the bolt prevents the door or access from being opened.

Cam-action indexing plungers equipped with a lock nut are positioned with the locknut opposite the main nut. To prevent unintentional loosening of the cam-action indexing plunger and to provide additional stability and safety.

To remove the cam-action indexing plunger or to release access, the bolt is retracted or unlocked.

Overall, cam-action indexing plungers help to create a safe environment, whether in industrial, public or private contexts. Their flexibility and versatility make them an indispensable element in the safety management of a wide range of facilities and systems.

What are barrel slide bolts?

A barrel slide bolt is a safety device that is used to lock doors, gates, hatches or other openings. The operating principle of cam-action indexing plungers aims to provide a secure and reliable locking mechanism. This is intended to control access to certain areas and ensure safety.

The barrel slide bolt consists of several components, including a housing, a bolt or locking element and, if necessary, a grip for manual operation. The housing is mounted on a fixed structure (e.g. door or gate frame). The actual locking element is the bolt or locking bar. This moves into a locking position to securely close the door or gate. This can be done by turning a grip, pushing a lever or using other manual or automated mechanisms.

Many barrel slide bolts have a grip or other fixture that allows the bolt to be moved manually and the lock to be opened or closed.

The use of high-quality materials such as stainless steel or other corrosion-resistant alloys ensures the durability and reliability of the barrel slide bolt, especially under different external pressures.

Barrel slide bolts are used in a wide variety of applications and industries. In industrial plants, they are used to control and restrict access to sensitive production areas in order to ensure the safety of employees and systems.

In machine construction, barrel slide bolts play a crucial role by protecting machines and systems from unauthorised access. They are used in warehouses and logistics centres to control access to storage areas and prevent theft.

Their versatility makes them indispensable safety components in numerous industries and applications.

The various standard parts in the cam-action indexing plungers, barrel slide bolts product family

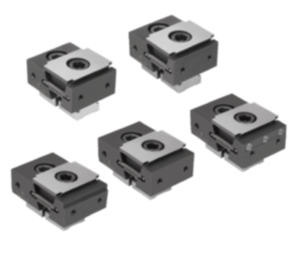

With a range of 20 products, the cam-action indexing plungers, barrel slide bolts category is one of norelem's smaller product families.

Cam-action indexing plungers, bolts, striking plates and barrel slide bolts are seen as umbrella terms for the individual product fields.

Cam-action indexing plungers

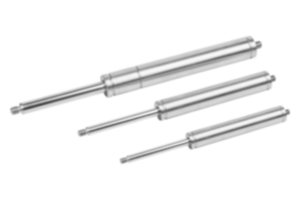

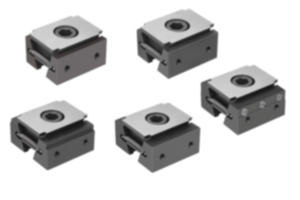

The wide norelem range comprises a total of 14 different cam-action indexing plungers, which differ in terms of their materials, functions and sizes.

The cam-action indexing plungers are made of robust stainless steel or steel to ensure maximum reliability and durability. The choice of material makes it possible to adapt the bolts to different environments and requirements, whether in industrial plants, machine construction or other areas of application. A particular variety is offered with regard to the design of the cam-action indexing plungers. You can choose between models with or without a locknut. The locknut serves as an additional layer of safety and prevents unintentional loosening of the cam-action indexing plunger. Cam-action indexing plungers with locknuts enable precise adaptation to the specific requirements of your application.

The cam-action indexing plungers from norelem have different grip lengths for use in different areas and applications. The grip lengths range between 25 mm and 51.3 mm. These different sizes allow flexible integration into various designs and systems. You can find more precise length specifications in the product details of the individual cam-action indexing plungers. The indexing pin diameter is also variable. The norelem range includes cam-action indexing plungers with locking pin diameters of 4 mm, 5 mm, 6 mm, 8 mm, 10 mm and 12 mm.

The following cam-action indexing plungers are available in the norelem product range:

- With hexagon

- With stop

- Made of stainless steel

- Made of stainless steel, with hexagon

- Made of stainless steel, with stop

Barrel slide bolts

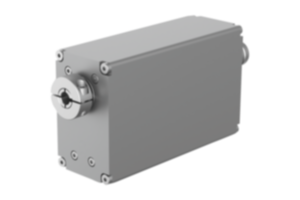

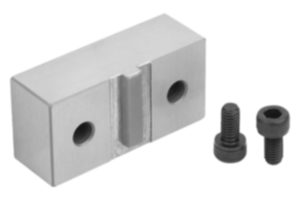

The housing of the barrel slide bolt is made of die-cast zinc to ensure maximum stability. The grip, underlays and slot fixings are made of hard-wearing PA thermoplastic. The bolt, on the other hand, is made of corrosion-resistant stainless steel.

The cam-action indexing plunger version has an attractive design with a silver-painted housing, black grip, underlays and slot fixings as well as a bright bolt. The spring-loaded locking piston, which is included in the scope of delivery, is particularly noteworthy. Two underlays for flat surfaces and two slot fixings for 8 and 10 mm slots on profiles are included for easy installation on various surfaces. The spring force of the locking barrel slide bolt is characterised by precision – with an initial force of around 5 N and a final force of approx. 15 N. The force ensures a gentle yet robust locking mechanism that meets your safety requirements. |

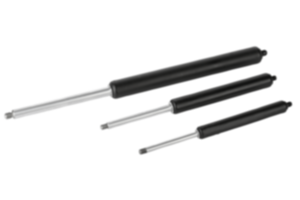

Lock grips with return spring

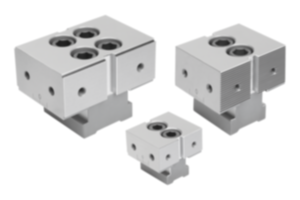

norelem offers three different bar variants for sale.

Lock grips with return spring upward or downward can be easily screwed to doors, hatches or hoods. The bolt is available in two versions, one is bevelled upward, the other downward. (see figure) The bevel allows the application to be opened or closed without actuating the bolt. |

| The lock grip with return spring made of aluminium is available for left-opening or right-opening doors. The lock grip can be locked in the open position. The return spring always brings the lock grip back to its original position. |

| The lock grip made of stainless steel can be locked automatically by simply pressing the application shut through the bevel. This bolt also has bevelled surfaces, which enables the application to be opened and closed as described. The lock grip is available in two different variants: bevelled upward or bevelled downward. (see figure) |

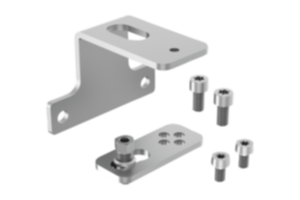

Locking plate

The locking plate is the counter part to the bolt and can simply be screwed onto the application. The range includes a striking plate that is available in different versions. If you opt for a steel striking plate, the surface is electro zinc-plated. If the plate is made of brass, it is chromed. Both striking plates are available with a screw diameter of 3.5 mm, 4.8 mm or 7 mm. |

norelem as your partner for cam-action indexing plungers and barrel slide bolts

norelem is your trusted partner for high-quality cam-action indexing plungers and barrel slide bolts. With an impressive range of 20 different product categories, norelem offers a variety that is characterised by material diversity and individual customisation options.

The products sold by norelem are characterised not only by their robustness, but also by their high quality and reliability.

Trust norelem as your supplier and rely on top quality and innovative solutions!